Nexus Connected Worker Operations

Elevate your operational performance

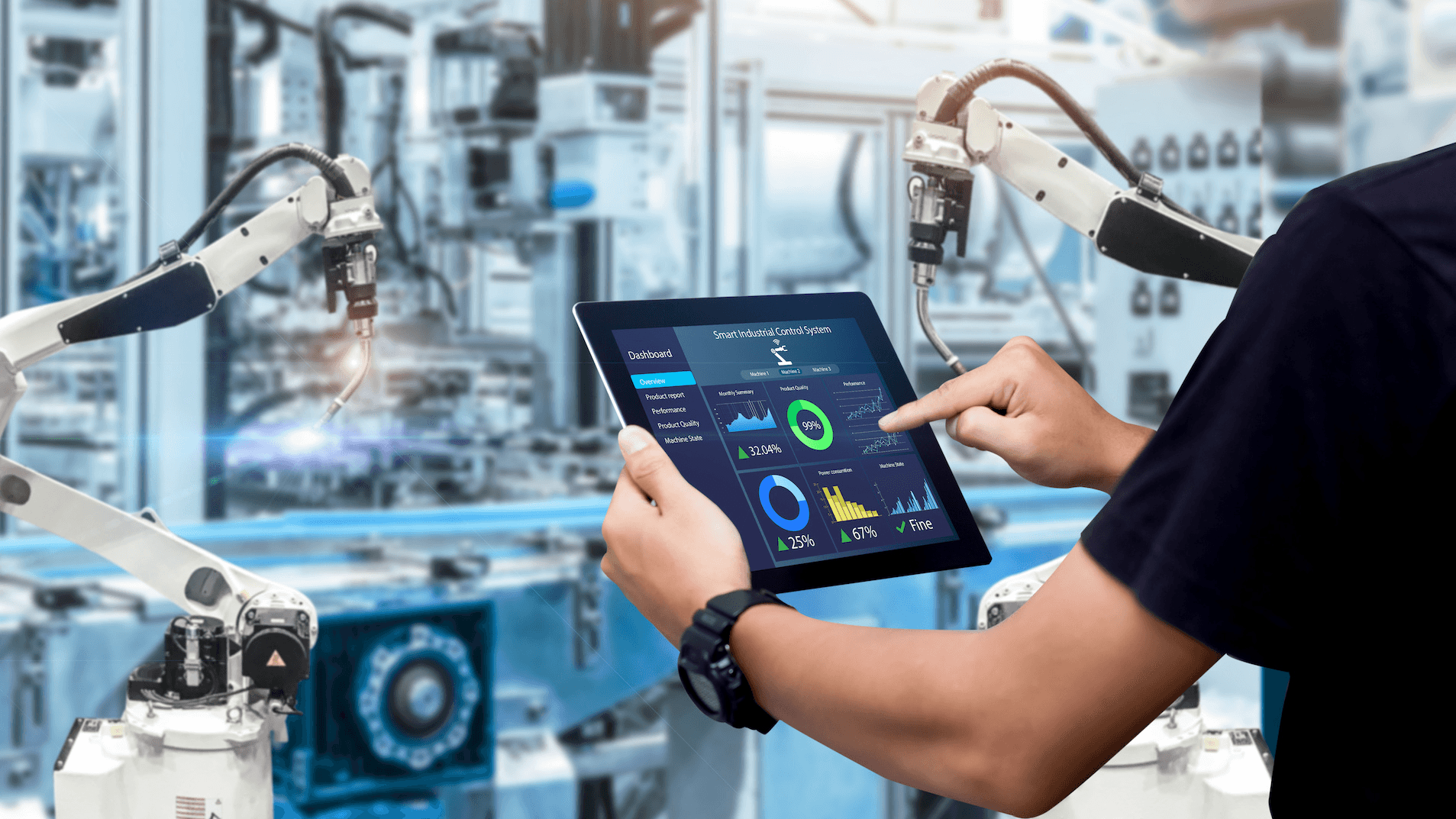

Drive excellence on the shop floor with Connected Worker Operations! Our solution uses downtime tagging for rapid issue resolution and substantially improves OEE. It optimizes shop floor operations with augmented-reality-based monitoring for maximum efficiency. Enhances precision and manages risk via mobile daily reporting that captures vital data. Drives shop floor excellence with execution and traceability features for planning, quality and more using dynamic OEE dashboards. It even eases digital transition through paperless travelers, ensuring seamless change implementation and foresight.

Benefits And Features

Digital workflows to optimize processes, increase availability and boost productivity.

Downtime Tagging

Downtime Tagging enhances manufacturing efficiency by allowing real-time tracking and categorization of production downtime causes. This feature helps identify recurring issues, enabling targeted improvements to minimize disruptions and boost productivity.

Paperless Traveller

The Paperless Traveler digitizes work instructions and documentation, providing workers with easy access to production information via digital devices. This feature reduces errors, improves communication, and supports sustainability by eliminating paper-based systems.

Real-Time Data and Insight

With real-time data collection and analysis, Nexus Connected Worker Operations provides valuable insights into operational performance. This enables quick decision-making and allows for continuous improvement by identifying trends and areas for optimization.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2026 Hexagon AB and/or its subsidiaries