© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Enable Collaboration and Drive increased simulation throughput.

Unlock product innovation and gain a competitive edge by accelerating time-to-market, driving intelligent decision-making, while enhancing collaboration, streamlining workflows, and saving costs.

Benefits And Features

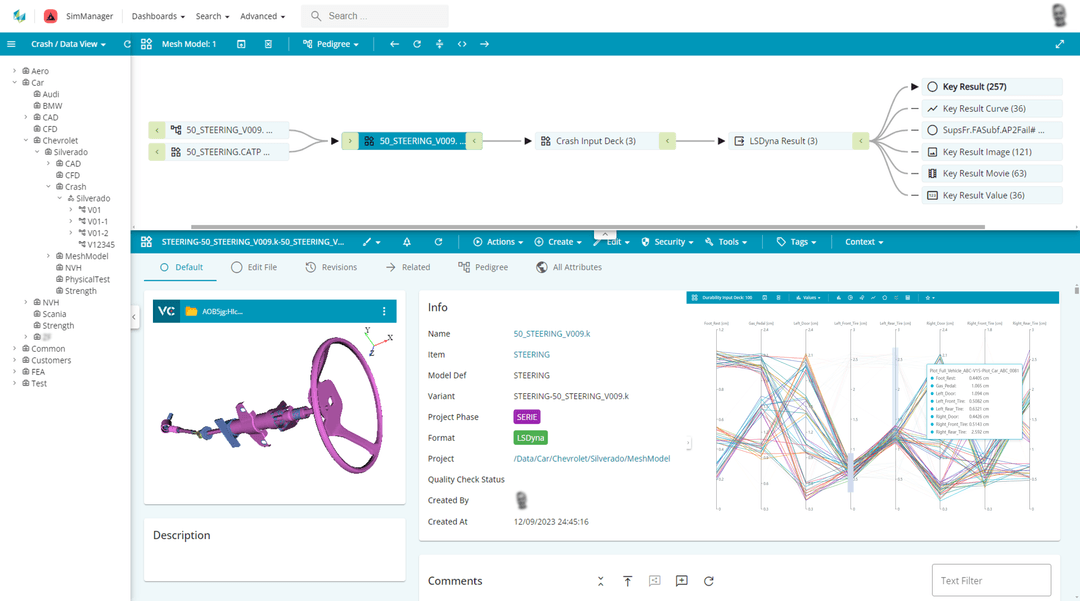

Simulate, analyze, and optimize with seamless data management

Data management – single source of truth

Centralize and streamline simulation data management with an intuitive, searchable, and secure environment. Improve efficiency with hierarchical navigation, and rapid data retrieval while leveraging interactive dashboards and reports with rich data comparison and visualisation.

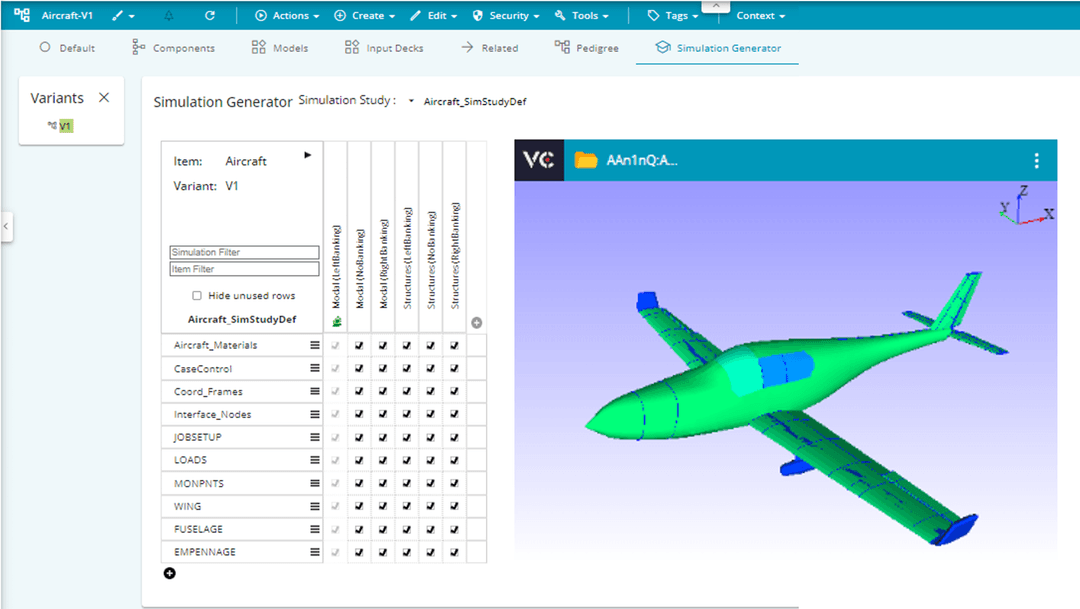

Process Automation & Orchestration

Automate complex simulation processes with template-based workflows, task orchestration, and intelligent job submission to HPC resources. Leverage productivity tools like Simulation Generator, Multi-Run, and auto-generated reports to reduce manual effort and increase throughput.

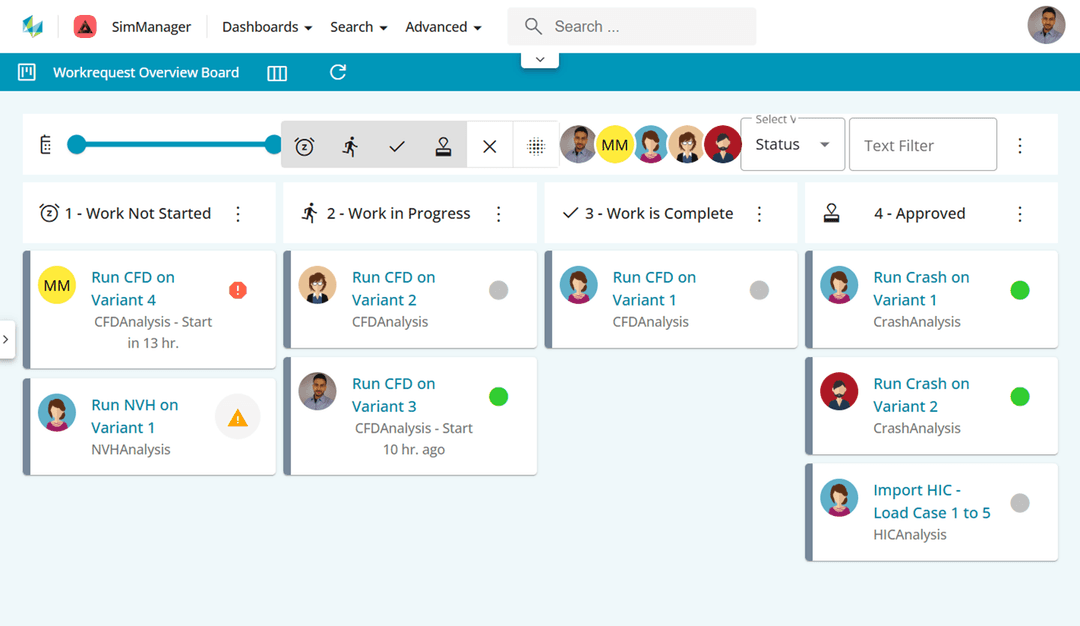

Seamless Collaboration – without boundaries

Enable seamless collaboration for globally distributed teams with a tools-agnostic platform that integrates effortlessly into diverse CAE ecosystems. Leverage multisite capabilities to ensure real-time data access, robust version control, and full traceability—enhancing transparency, compliance, and workflow efficiency across locations.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Enable Collaboration and Drive increased simulation throughput.

Unlock product innovation and gain a competitive edge by accelerating time-to-market, driving intelligent decision-making, while enhancing collaboration, streamlining workflows, and saving costs.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

This product does not offer any software downloads.

Frequently Asked Questions

SPDM, or Simulation Process and Data Management, is crucial in Computer Aided Engineering (CAE) as it efficiently handles the large volume of data generated by simulations. CAE is vital for rapid product development and cost reduction by minimizing physical prototyping/testing. However, CAE's diverse operations pose challenges in simulation volume, accuracy, speed, and cost. SPDM is designed to manage this simulation data and processes effectively.

SPDM systems are purpose-built for managing simulation data and processes, such as Finite Element Analysis and Computational Fluid Dynamics, which are increasingly popular. The rising data volumes demand efficient management for quick answers to design questions and streamlined product development. SPDM systems benefit companies of all sizes by saving time and resources in the design and development process.

Many manufacturing companies use Simulation Process and Data Management (SPDM) to stay competitive. SPDM enhances productivity, reduces errors, and provides insights into the engineering cycle. It stores and traces all simulation data, facilitating "what if" studies. Centralizing compute capacity and licenses leads to significant IT cost savings. Users like BMW and Audi have reported substantial savings in preprocessing, post-processing, and human effort. Integrating SPDM with simulations offers value by increasing efficiency, reducing errors, and ensuring data certainty in engineering workflows for design and production.

Here is a detailed list to our supported platforms:

SimManager is an open system that is agnostic with respect to the applications and file types that we work with.

SimManager is an on-premise installation (but customers can install in cloud instances if that is preferable). With a combination of projects, roles, and release levels, users can work privately in a sandbox to experiment and then promote data to a point where it can be used collaboratively.

SimManager has a multi-site capability that enables selective data sharing between different geographical regions. There is a difference in synchronizing metadata and large files to appropriately manage the volume of data being transferred to reduce unnecessary replication of data.

SimManager couples both data and process management very closely, which ensures that when processes are run, the process of securing that data in SimManager happens automatically and does not require secondary steps to be executed manually.